Main Working Mode:

Main Working Mode:

Features:

Features:

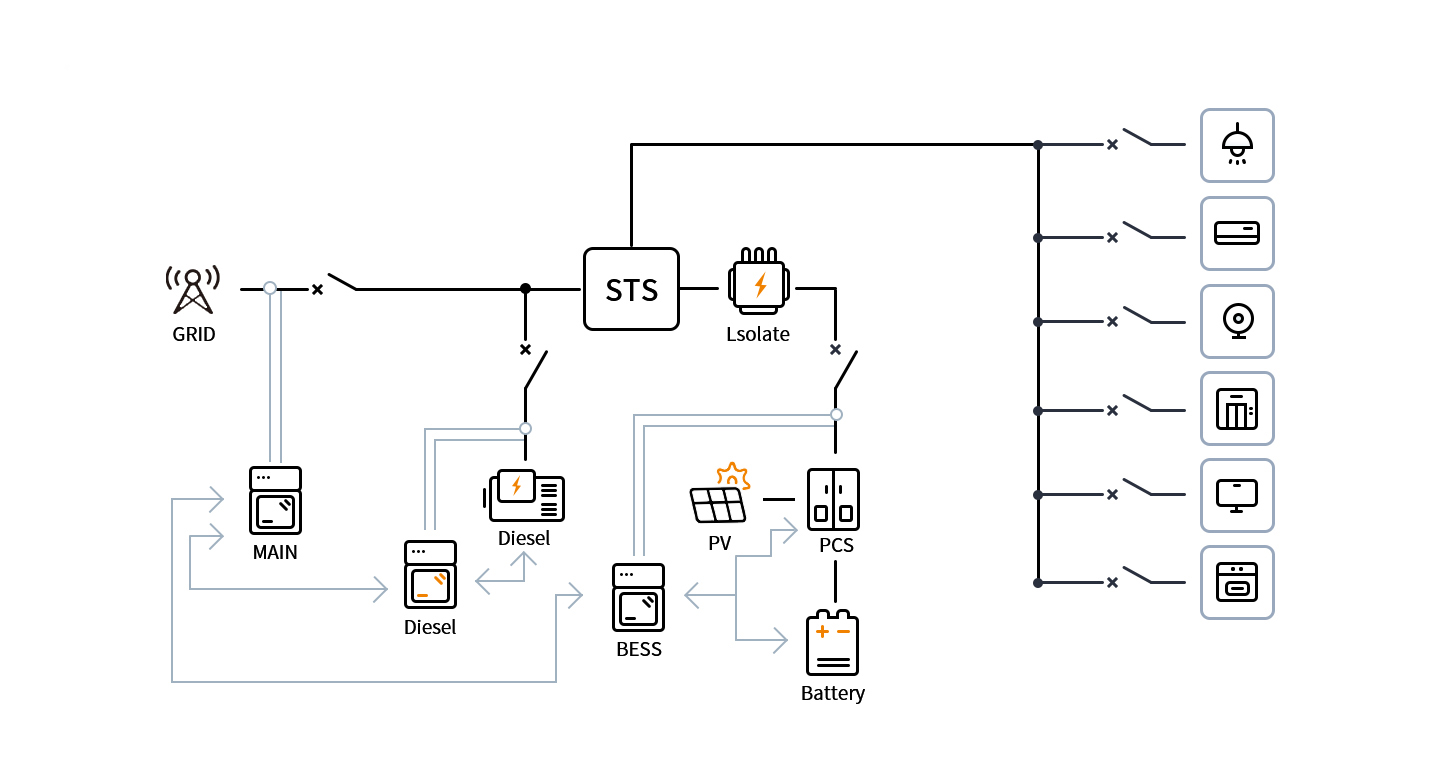

Topology Map:

Topology Map:

Lighting Electricity:

Lighting Electricity: Office Electricity:

Office Electricity: Production Electricity:

Production Electricity:

Lighting Electricity:

Lighting Electricity: Office Electricity:

Office Electricity: Production Electricity:

Production Electricity: